tel.: +420 491 523 618

genera.broumov@tiscali.cz

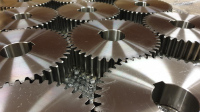

Gear wheels

Gear wheels

Spur gears

Spur gears

Spur gears with material quality certificate

We manufacture spur gears with straight teeth and helical gearing up to the diameter of 800 mm. We will provide you with gears based on the drawing you supplied or – in special cases – based on a sample. The gears are manufactured using conventional machines as well as CNC technology. With CNC technology we have the possibility of complete automation of gears production.

We manufacture spur gears with straight teeth and helical gearing up to the diameter of 800 mm. We will provide you with gears based on the drawing you supplied or – in special cases – based on a sample. The gears are manufactured using conventional machines as well as CNC technology. With CNC technology we have the possibility of complete automation of gears production.

In the production of gearing we use both tools made of HSS material and also highly productive tools from PM+ material (Speedcore).

Why order your spur gears from us?

- We are happy to accommodate the wishes of our customers

- Gearing quality from accuracy DIN 7 (depending on the tool used)

- We can offer the gears including keyway grooves (up to 16 mm wide - NC technology)

- Gears can be manufactured with ground holes

- In special cases, we can produce samples (including measurement protocol)

- We can provide a certificate of material quality and heat treatment upon request

- We will ensure surface treatment of products (galvanizing, chrome plating, blacking, etc.)

- We will draw-up an indicative price quotation

Production of spur gears with straight teeth

Module range m = 0.8 - 10 (up to m5 and diam. of 320 mm - CNC productive technology)

Range of gear diameters:

- 20 - 500 mm (up to maximal module m = 10)

- 20 - 800 mm (up to maximal module m = 6)

Production of spur gears with helical gearing

With gearing angle of approx. 15 degrees:

- max. wheel diameter 600 mm

- max. gearing width 250 mm

With gearing angle of approx. 60 degrees:

- max. wheel diameter 450 mm

- max. gearing width 90 mm

Production of external spur gears

- Range of gearing modules in metric series: 0.8 – 10

- For helical teeth, max. angle ß = 30 °

- Maximum addendum circle diameter is 600 mm

- Minimum machining diameter is 20 mm

- The gearing complies with accuracy class 7 - 9 according to ČSN 01 4682 – milled wheels standard,

- Surface roughness is p from 1.6 Ra above depending on the tool used

The production of gears has a long tradition in our company. Reliability and quality of our work is proven by numerous references from our satisfied clients. Complete production automation - semi-finished products conveyor makes sense for large deliveries of 10,000 or more units, given the cost of the fixtures.

Do not hesitate to contact us if you have any questions. Use our contact form, we will be happy to help you!